Diamond Dressing Products

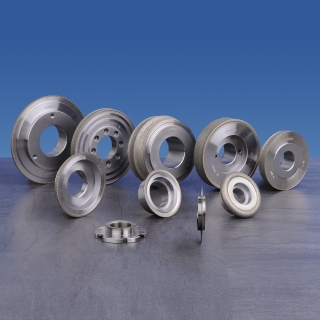

CNC Dressing Discs

Dress conventional and vitrified Superabrasive grinding wheels on CNC grinding machines for either straight or form dressing.

Plunge Dressing

Rolls contain the entire workpiece geometry and transfer this geometry to the grinding wheel by a single in-feed motion.

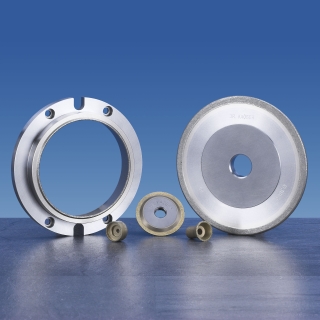

Dressing CBN Wheels RIG

RIG tools are plated diamond tools with a single layer of diamond attached by a nickel bond to a steel body.

Dressing CBN Wheels RI

RI tools have a thick layer impregnated with diamond grit for longer life. RI tools can be shaped during manufacture with precise profiles.

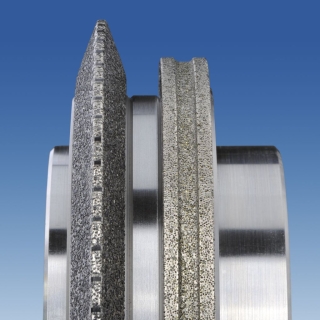

Gear Grinding

Rotary Diamond dressing tools are used to profile gear grinding wheels. Module range is 0.35mm to 10mm (72 to 2.54 DP). Newer gear dressers use PCD reinforced dresser tip on a direct-plated diamond dresser.

MCD Dressing

MCD Dressers are stationary tools with monocrystalline diamond for dressing complex profiles and radii on grinding wheels. They offer long life, stability, and repeatability, especially when dressing ceramic abrasive wheels.

PCD Workrest Blades

Dr. Kaiser offers custom made Workrest Blades for all major brands of Centerless Grinders. These blades improve geometrical and dimensional accuracies and surface finish. Blades are available with Eddy-Current Sensors for in-process inspection of ground workpiece surfaces on thru- feed grinding.

Superabrasives

MB Superabrasives

This SLM company offers custom engineered, single-layer brazed tools for cutting, grinding and shaping advanced composites, friction materials, fiberglass, steel, cast iron, ceramics & carbon fibers.

Dr. Kaiser

Dr. Kaiser manufactures a wide range of plated grinding products in a durable nickel matrix. Proprietary technology allows the concentration of CBN or diamond to be modified precisely prior to the plating process.

Conventional Grinding

IGA Abrasives

IGA offers engineered grinding, honing and dressing products. Excels in small diameter ID grinding wheels in AlO, SiC, ceramic & CBN abrasives. Also manufactures a wide range of superfinishing stones (hones) in grain sizes up to 1000 grit and a line of dressing sticks.